Our core business

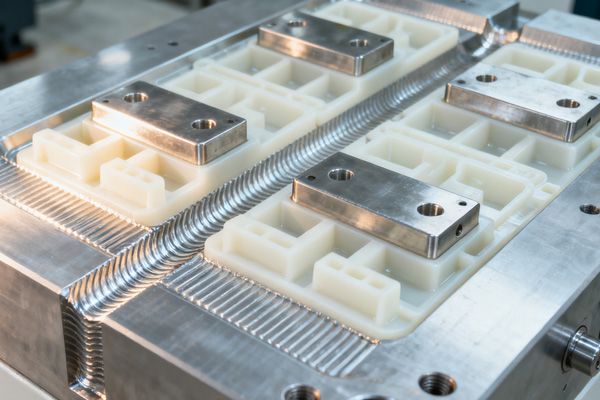

We focus on the research, development and manufacturing of precision stamping molds and precision injection molds.

Provide one - stop services from the manufacturing of precision stamping molds and precision injection molds to the corresponding molding production.

The company focuses on the manufacture of high - quality precision injection molds and precision stamping molds. The product specifications cover those below 400 - ton class (corresponding to the tonnage of injection molding machines and stamping equipment). With stable quality and technical strength, the products sell well in Japan, the United States, and Southeast Asian markets. Currently, the company's mold - making capacity ranges from 20 tons to 400 tons (suitable for the tonnage of injection molding machines and stamping equipment), and it has significant technical advantages - especially excelling in core processes such as injection molding, two - color molding, insert molding, precision stamping molding, and progressive stamping molding, which can meet complex molding requirements in multiple scenarios.

The business areas center around automotive parts, and also widely cover multiple industries such as printers, OA equipment, digital cameras, and electronic components. It can accurately match the product characteristics of different industries and fully support the mass - production needs of customers in various fields.

From the very beginning of the mold design stage, we have always adhered to the core principles of "low cost, short delivery time", providing customers with an integrated full - process service from design, manufacturing to molding and after - sales. For mass - production projects, by establishing a regular mold (including injection and stamping molds) management and maintenance mechanism, continuously optimizing the production process, we have built a stable and reliable quality control system and a flexible and efficient supply chain response mechanism to ensure a smooth and efficient mass - production process.

To ensure service quality, the company is equipped with a full set of professional equipment from mold design, injection molding, stamping molding to mold assembly, finished - product inspection, and precision measurement. Always adhering to the concept of "reliable manufacturing", by combining hardware strength with refined management, we effectively ensure both product quality and supply stability.

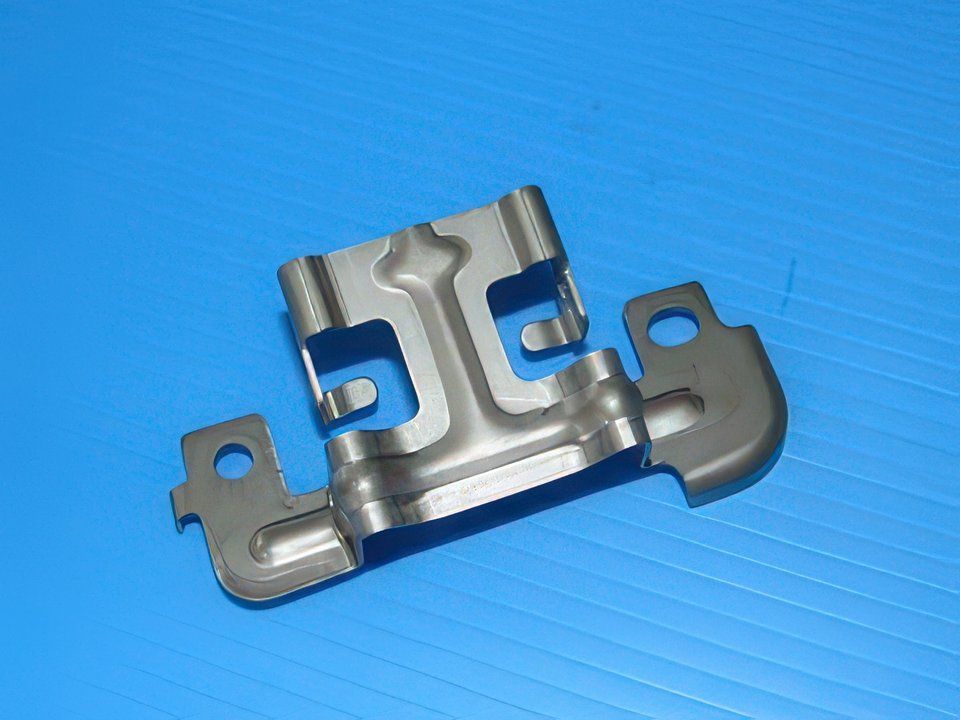

精密冲压模具

承接模具设计、制作单发型、顺送型的设计、制作。擅长汽车相关、工业机械、家电、OA机器等对尺寸公差要求严格的零件。从20吨到400吨,压力机齐全。可对应不锈钢、铁、铝等所有材质。此外,利用迄今为止加工多种产品所积累的技术知识、最新设备和技术,实现高品质化。

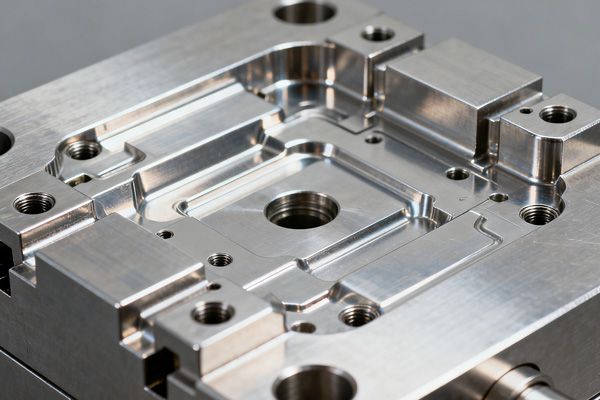

精密注塑模具

公司专注于高品质注塑模具制造,产品涵盖 400 吨级以下规格,畅销日本、美国及东南亚市场。每年模具型面制作量约 400 面,模具制作能力范围为 20 吨至 400 吨(成型机吨数)。尤其擅长注塑成型、双色成型及嵌件成型工艺。

Application areas

汽车行业

汽车零部件的精密制造,包括外观件、功能件等。

家电行业

家用电器外壳及内部组件的精密成型。

医疗器械

高精度医疗设备部件,符合严格的卫生标准。

数码产品

智能手机、平板电脑等消费电子产品的精密组件。

Application areas

需求分析

深入了解客户需求,制定技术方案

设计开发

使用CAD/CAE软件进行模具设计和仿真分析

精密加工

采用先进的CNC设备进行精密加工

装配调试

专业技师进行模具装配和试模调试

质量检测

严格的质量控制和产品检验

交付服务

准时交付并提供完善的售后服务

Comprehensive technical support services

我们建立了完善的质量管理体系,从原材料采购到成品出厂,每个环节都进行严格的质量控制:

-

原材料质量检测

-

加工过程质量监控

-

成品全检和抽样检验

-

质量追溯体系

-

客户满意度调查

通过严格执行质量标准,我们确保每一套模具都达到或超过客户期望。

Are you ready to start your project?

Our expert team is ready to provide you with customized mold solutions at any time.